Manufacturing Update

Share

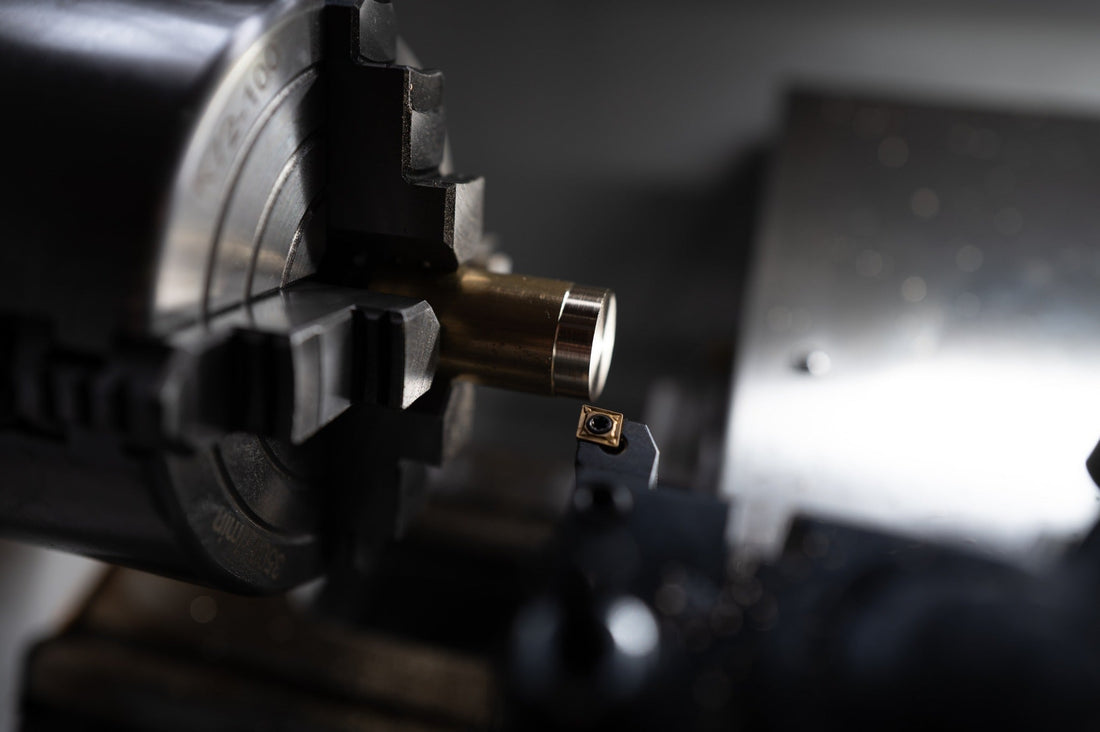

We have a lathe now! Specifically at Tormach 8L CNC lathe which can cut all the materials we use for mouthpieces & rims!

This lets us do a couple things; 1 - with supply chain uncertainty it lets us ensure that we'll be able to produce mouthpieces regardless. 2 - it lets us make prototypes, custom work and small batches in-house for much lower lead times. And 3 - we can run a few off when we're waiting for big batches to help with the dreaded "Backordered" situation.

What we're not doing (just yet) is moving all production in-house. The lathe is lacking some automation that features that would let us truly handle all production at scale. We're ordering batches of 10+ from a contract shop that has highly automated lathes that do tool changes, zeroing etc all with no human intervention.

Will the in-house, made-in-USA production be the same as the large, highly consistent batches? We hope so - we've invested in some precision measuring devices too to help get everything very consistent. However if you have a perceived preference on a model that's made both ways (G, GM, GS, M), get in touch and we can source you a sample from whichever method.